- Home

- Granule Packaging Machine

- Biscuit Packing Machine

Biscuit Packing Machine

Custom Packaging Machine for Biscuit

BG Machinery offers a wide range of packaging equipment for atta biscuit, dog biscuit, cookies, handyman cookies, marcato biscuits, Italian cookies and Khosla biscuits. Biscuit manufacturers choose BG Machinery automated packaging and sealing machines for their ease of use, durability, and high speeds necessary for packaging cookie, snack food and prepared food products.

4 side seal , 3 side seal bag, Stick pack ,Stand up bag, Pillow bag, Quad seal bag and Flat bottom bag is avaliable

- Wide range of cookie machine options

- High speed & Low failure

- Flexbile Package & Sustainabilty

- Competitive Price with reliable quality

- On time delievry & Perfect after-sales service

Industrial Cookie Machine for Sale

Small Biscuit Packing Machine

The vertical form fill seal machine is tailored for creating bags from a roll of film, filling them with cookies, and then sealing them. It's highly efficient for large-scale packaging and offers quick changeover times between different bag sizes, which is ideal for varying cookie packaging needs

Premade Pouch Packing Machine

Suitable for packing cookies in premade pouches, this type of machine is excellent for ensuring high-quality presentation and is typically used when the aesthetics of the package are crucial. It's versatile for different pouch sizes and types.

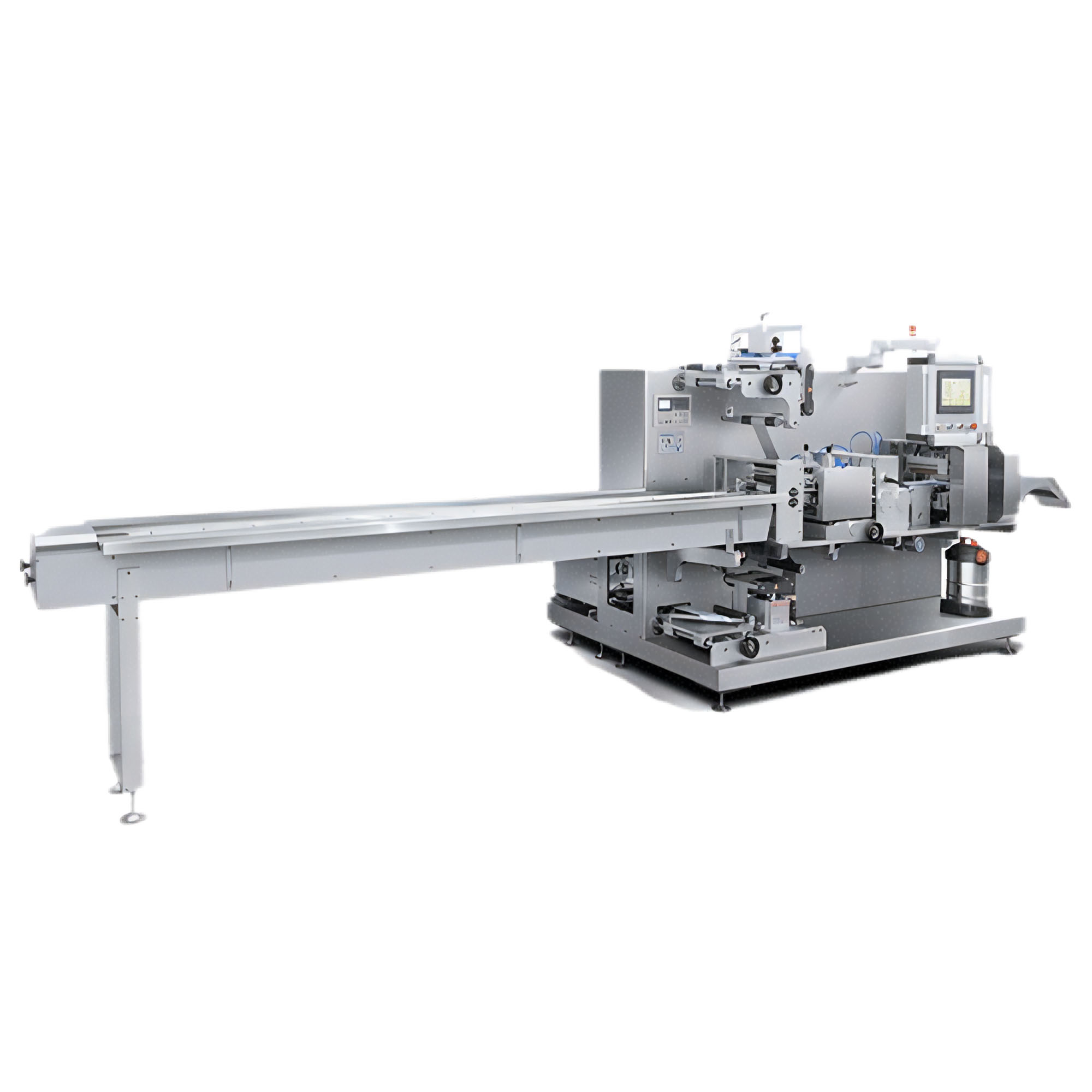

Horizontal Form Fill Seal (HFFS) Machines

This machine operates horizontally and is ideal for softer or more fragile cookies that need gentle handling. It can efficiently package cookies in a variety of wrapper styles, including pillow packs, and offers automated control for precision packaging

Horizontal Flow Wrapper

Specifically designed for individual or grouped cookies, the horizontal flow wrapper packages cookies in a continuous manner. This system is great for high-speed packaging, providing consistent quality and seal integrity

Video Gallery

Biscuit Packing Machine Video

Skyrocket Your Business with BG Machinery

How can we order the right machine?

How can we check your machine quality after we place an order?

You will receive photos and videos of the machine every 5-10 days so that you can assess its running condition. In addition, you’re welcome to check the machine by yourself at our factory.

Why we should choose you?

- Professional team 24 hours provide service for you

- 12 months warranty

- Life time technical support no matter how long you have bought our machine

- Oversea service is available.

What about your payment?

T/T by bank account directly L/C at sight

Ultimate Guide

Biscuit Packing Machine : The Complete Guide 2025

Table of Contents

In the realm of food packaging, biscuit packing machines play a crucial role in preserving the freshness and quality of these delectable treats. These machines are designed to efficiently package biscuits in various shapes and sizes, ensuring their safe delivery to consumers.

What is a Biscuit Packing Machine?

A biscuit packing machine is an automated or semi-automated device that packages biscuits into individual units or multipacks. It typically consists of a conveyor system, a wrapping mechanism, and a sealing system. The machine can be customized to handle different biscuit sizes, shapes, and packaging materials.

Types of Biscuit Packing Machines

1. Flow Wrapping Machines:

Flow wrapping machines are widely used for packaging individual biscuits. They wrap the biscuits in a continuous film, creating a tight and protective seal. These machines offer high speed and efficiency, making them suitable for large-scale production.

2. Vertical Form Fill Seal (VFFS) Machines:

VFFS machines form a pouch from a roll of film, fill it with biscuits, and seal it. They are versatile and can handle a wide range of biscuit shapes and sizes. VFFS machines are ideal for packaging biscuits in bulk or in individual portions.

3. Horizontal Form Fill Seal (HFFS) Machines

HFFS machines operate similarly to VFFS machines, but they form the pouch horizontally. They are suitable for packaging biscuits in larger quantities, such as family-sized packs.

4. Rotary Die Cut Machines:

Rotary die cut machines use a rotating die to cut and shape the packaging material. They are commonly used for packaging biscuits in unique or decorative shapes.

5. Overwrapping Machines:

Overwrapping machines wrap biscuits in a pre-formed tray or carton. They provide additional protection and enhance the presentation of the product.

Benefits of Using a Biscuit Packing Machine

Biscuit packing machines offer numerous benefits, including:

- Increased Efficiency: Automating the packaging process significantly reduces labor costs and increases productivity.

- Improved Quality: Machines ensure consistent and precise packaging, minimizing product damage and maintaining freshness.

- Enhanced Shelf Life: Proper packaging protects biscuits from moisture, oxygen, and contamination, extending their shelf life.

- Reduced Waste: Machines optimize packaging materials, minimizing waste and environmental impact.

- Increased Brand Value: Professionally packaged biscuits enhance brand image and consumer appeal.

How Does a Biscuit Packing Machine Work?

Biscuit packing machines are automated systems designed to efficiently package biscuits in various formats. The process typically involves several key steps:

1. Biscuit Feeding:

Biscuits are fed into the machine through a conveyor belt or a hopper. The machine’s sensors detect the presence of biscuits and trigger the packaging process.

2. Biscuit Orientation:

To ensure proper alignment within the packaging, the machine uses sensors or mechanical devices to orient the biscuits correctly. This step is crucial for efficient and aesthetically pleasing packaging.

3. Packaging Material Selection:

The machine selects the appropriate packaging material, such as plastic film or foil, based on the desired packaging format. The material is unwound from a roll and fed into the packaging area.

4. Biscuit Loading:

The oriented biscuits are loaded into the packaging material. The machine uses a combination of mechanical arms and vacuum suction to gently place the biscuits into the packaging.

5. Sealing and Cutting:

The packaging material is sealed around the biscuits using heat or adhesive. The machine then cuts the excess material to create individual packages.

6. Packaging Format:

Biscuit packing machines can produce various packaging formats, including single-serve packs, multi-packs, and bulk packs. The machine’s settings can be adjusted to accommodate different package sizes and shapes.

7. Quality Control:

Throughout the packaging process, the machine performs quality control checks to ensure that the biscuits are properly packaged and meet the desired specifications.

8. Output:

The packaged biscuits are discharged from the machine onto a conveyor belt or into a collection bin. The machine’s output speed can be adjusted to meet production requirements.

Additional Features:

Modern biscuit packing machines often incorporate additional features to enhance efficiency and flexibility:

- PLC Control: Programmable logic controllers (PLCs) provide precise control over the machine’s operations, allowing for easy adjustments and customization.

- Touchscreen Interface: User-friendly touchscreens simplify machine operation and provide real-time monitoring of the packaging process.

- Data Logging: The machine can record production data, such as output, packaging speed, and downtime, for analysis and optimization.

- Sanitary Design: Biscuit packing machines are designed with sanitary materials and features to prevent contamination and ensure food safety.

Factors to Consider When Choosing a Biscuit Packing Machine

When selecting a biscuit packing machine, consider the following factors:

- Production capacity: Determine the required output speed to meet your production needs.

- Biscuit size and shape: Choose a machine that can accommodate the specific dimensions and shapes of your biscuits.

- Packaging material: Select a machine compatible with the desired packaging material, such as film, paper, or carton.

- Automation level: Consider the level of automation required, from manual to fully automated systems.

- Budget: Determine the available budget and compare the costs of different machines.

- Reputation and Experience: Research potential suppliers and choose one with a proven track record in the industry.

- Technical Support: Ensure the supplier provides comprehensive technical support and spare parts availability.

- Customization Options: Consider suppliers who offer customization options to meet your specific requirements.

- Warranty and After-Sales Service: Look for a supplier who offers a comprehensive warranty and reliable after-sales service.

Ideal Custom Packing Machine from BG Machinery

Biscuit packing machines are essential equipment for the efficient and effective packaging of biscuits. By understanding the different types, benefits, and operation of these machines, manufacturers can make informed decisions to optimize their packaging processes and deliver high-quality biscuits to consumers.

Want to Get Biscuit Packaging Machine Price?

Why we're different