Stand Up Pouch Packing Machine | LTC8-260

- Home

- Food Machine

- Stand Up Pouch Packing Machine | LTC8-260

Feature

- Adopt Siemens PLC control system

- Easy to change product filling without setting

- Adopts intelligent temperature control & safe protection

- Wide application:food,non-food and phamacy.

- Fill measure accurately 99.99%

- Convenient adjustment and full automation.

- OEM&ODM is avaliable

- Super maintence&On time delivery

- Competitive price and reliable quality

Video Gallery

Playlist

The premade pouch packing machine, also known as the stand-up pouch packing machine, is an automated device that is designed to fill and seal pre-made stand-up pouches. The purses are frequently equipped with a re-closable zip, which facilitates their reuse by consumers. Additionally, they are designed to stand on their own. By automating the process and guaranteeing consistent product quality through their precise filling and sealing technology, stand-up pouch-filling machines enhance productivity and decrease labor costs.

Some of the product types for which the machines are suitable:

Food: solid foods such as chocolates, candies, cereals, biscuits, cakes, puffed foods, etc.

Granules: nuts, capsules, seeds, etc.

Powders: spices, milk powder, washing powder, fine sugar, etc.

Liquids/sauces: detergents, fruit juices, beverages, ketchup, jams, etc.

Pickled products: e.g. carrots, etc.

Stand-up pouch packing machines provide a broader selection of packaging alternatives, enabling you to select the most suitable bag type for the unique requirements of your product. Especially well-suited for products that necessitate simple portability and a stand-up display.

Summary

2. The speed of this machine can be changed by converting frequencies over a range. The real speed depends on the type of product and the pouch.

3. An automatic device can check the condition of the bags, their contents, and their seals. 1. The method doesn’t feed bags, fill them, or seal them. 2. No bag opening or opening mistake, no filling, and no sealing 3. No closing or filling.

4. Parts of the product and pouch that come into touch with each other are made of stainless steel and other high-tech materials to keep the products clean.

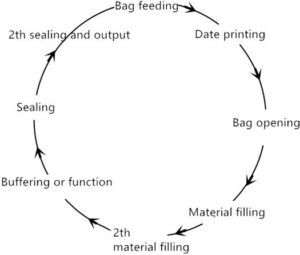

Working Process

1. Bag feeding

2. Date printing

3. Zipper opening

4. Bag opening

5. Material filling

6. 2th material filling

7. Buffering or function

8. 2th sealing and output

Sample Bag

Premade bag pouch filling machine can handle a variety of bag types including, but not limited to, stand-up bags, bags with zips, four-sided sealed bags, three-sided sealed bags, and more.

Attention: If the bag sizes fall outside of the specified range, we will offer customization options to fulfil any unique size requests.

- Zipper/Resealable/Ziplock bag packaging —— between zipper and bag mouth distance at least 2.5cm.

- Gusset bag packaging —— bag gusset width within 50mm, if the bag mouth is too small the products can’t fill completely, and can’t be packed.

- Spout bag packaging —— spout at the side of the bag, sealing sizes at least 50mm.

- Pallet bag packaging —— pallet in bags, pallet length lower bag mouth at least 3cm.

Machine Structure

FAQ

Q: Where is your factory location? How can | visit your factory?

A: Our factory is located in Rul’An Wenzhou City Zhejiang Province. We warmly welcome your visit. Our city is near

ShangHai. You can fly to Wenzhou airport and we can arrange car to pick you up.

Q: How can i know your machine is designed for my product?

A: if you don’t mind, you can send us sample and we test it on the machine. We will take video and clearer picture for

you. If it is possible, we can make video call or video meeting online to showing

Q: How can | trust you for the first time business?

A: Please note our above business license and certificate. And if you don’t trust us,

then we can use Alibaba Trade Assurance service. it will protect your money during the whole stage of the

transaction.

Q: How about the after-service and guarantee period?

A: We make the guaranteed time 12 months from the machine’s arrival in the buyer’s factory and we have a professional

team with an experienced technician to serve abroad and do the best after service to ensure the machine’s whole life

usage.

Q: How do we contact you?

A: Please leave a message and click “Quote” to send us an inquiry.

Q: Your delivery is 10-60 days, how can i realize my order machine?

A: After we get your deposit in our bank, we will provide you a machine-making tracking sheet. And we will take photos and update the sheet every 5-10 days. If you need video to see the machine making process, please tell us, we also can provide it every 5-10 days.

Bags size | W:80~210mm L:100~300mm | W:120~250mm L:100~400mm | W:200~300mm L:100~400mm |

Bag type | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag |

Filling Volume | 30–1900g depending on the type of products | 30-2000g depending on the type of products | 100-2500g depending on the type of products |

Capacity | 25-60 bags/min for different materials and different bag | 25-60 bags/min for different materials and different bag | 25-60 bags/min for different materials and different bag |

Dimension | 1.140*1.500*1.560m | 2.46*1.83*1.46m | |

Weight & power supply | 400kgs/1500kgs/1600kgs-1800kgs 380v 50HZ 3P 2.5kw-5kw | ||

Compress air requirement | 0.6-1m³/min supply by user | ||

Working flow | 1. Bag feeding | ||

Client Testimonials

About Bengang Machinery

BenGang Machinery is a filling & packing machine factory which is long established engineering company which combined with R&D DPT, machine producing DPT, marketing DPT and after-sales team DPT.