- Home

- Powder Filling Machine

- Chemical Powder Packing Machine

Chemical Powder Packing Machine

Customize Packaging Machine For Chemical Powder

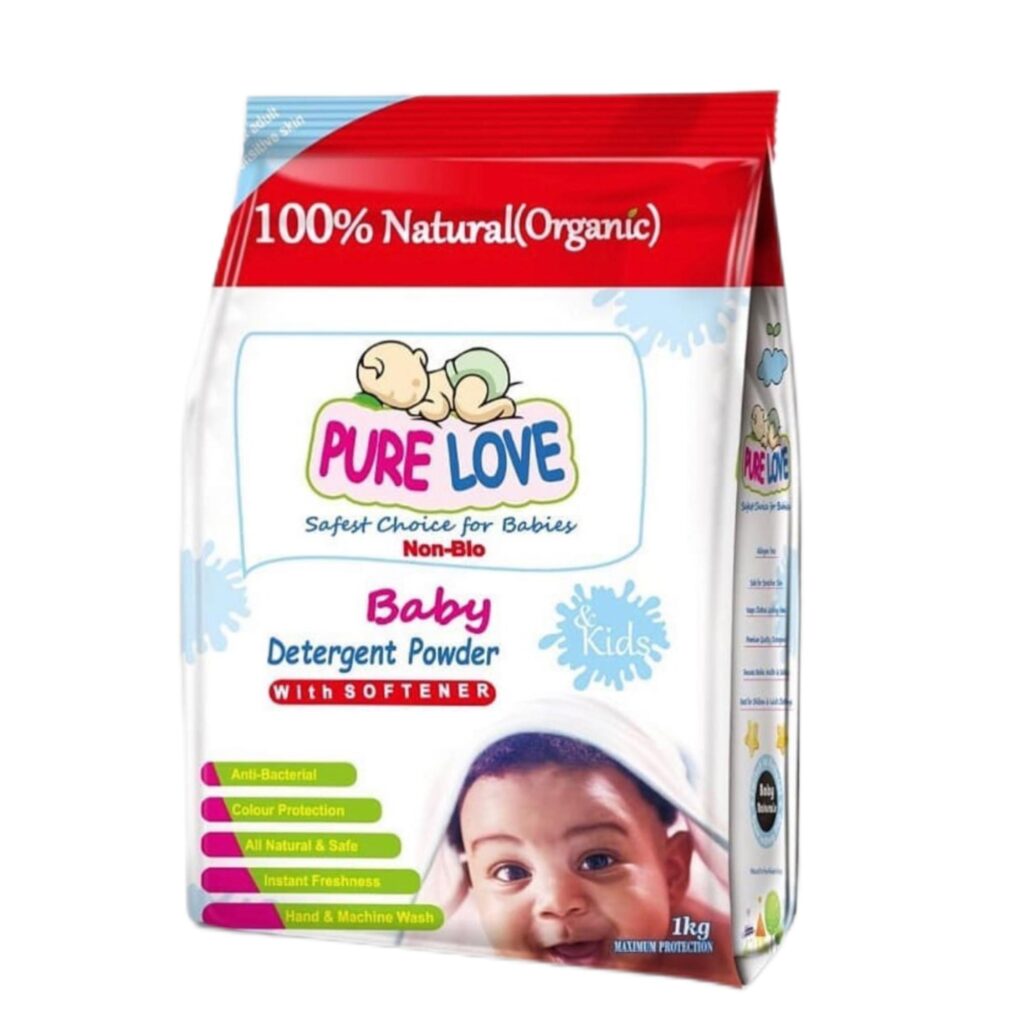

BG Machinery offers a wide range of chemical powder packing machines for you.80+ chemical powder manufacturers choose BG Machinery automated packaging and sealing machines for their ease of use, durability, and high speeds necessary for packaging pharmaceutical powders, cosmetic powders, cleaning powders, detergent powders, food additives, bleaching powder and dry chemical powder products.

4 side seal, 3 side seal bag, Stick pack,Stand up bag, Pillow bag, Quad seal bag and Flat bottom bag is available

- Wide range of powder filling machine options

- High speed & Low failure

- Flexbile Package & Sustainabilty

- Competitive Price with reliable quality

- On time delievry & Perfect after-sales service

Chemical Powder Packing Machine For Sale

Vertical Form Fill Seal Machine

Vertical Form Fill Seal (VFFS) machines are widely used for packaging chemical powders. These machines form bags from a continuous film roll, fill them with the chemical powder using an auger filler or similar mechanism, and seal them. This process is ideal for high-volume packaging needs, providing speed and precision

Premade Pouch Packing Machine

Doypack machines are designed to fill and seal premade pouches with chemical powders. The premade pouch system is advantageous for its ability to handle diverse pouch specifications and enhance package integrity, especially beneficial for hazardous or sensitive chemical powders

Auger Filling Machine

Auger fillers dispense precise amounts of powder into a container or packaging system. They are essential for achieving accurate dosages and minimizing product waste, commonly integrated with VFFS or other packaging machines to streamline the filling process for chemical powders

Video Gallery

Powder Filling Machine Video

Skyrocket Your Business with BG Machinery

How can we order the right machine?

How can we check your machine quality after we place an order?

You will receive photos and videos of the machine every 5-10 days so that you can assess its running condition. In addition, you’re welcome to check the machine by yourself at our factory.

Why we should choose you?

- Professional team 24 hours provide service for you

- 12 months warranty

- Life time technical support no matter how long you have bought our machine

- Oversea service is available.

What about your payment?

T/T by bank account directly , L/C at sight

Ultimate Guide

Chemical Powder Packing Machine : The Complete Guide 2025

Table of Contents

What is a Chemical Powder Packing Machine?

A chemical powder packing machine is a specialized device designed to fill and package powdered chemicals into containers such as bags, pouches, or bottles. It automates the packaging process, reducing manual labor and increasing efficiency.

What are the Benefits of Using a Chemical Powder Packing Machine?

- Increased Efficiency: Automating the packaging process significantly reduces labor costs and increases productivity.

- Improved Accuracy: Dosing systems ensure precise filling, minimizing product waste and maintaining product quality.

- Reduced Contamination: Enclosed systems prevent contamination of the powder during the packaging process.

- Enhanced Safety: Automated machines eliminate the risk of manual handling and exposure to hazardous chemicals.

- Customization: Machines can be customized to meet specific packaging requirements, such as container size, filling speed, and labeling options.

What Equipment Is Used For Packing Chemical Powder?

1. Auger Filling Machines:

Auger filling machines utilize a rotating auger to dispense powder into containers. They are suitable for powders with good flowability and are commonly used for filling bags, bottles, and drums.

2. Volumetric Cup Filling Machines:

These machines use a rotating cup to measure and dispense powder. They are ideal for powders with poor flowability and are often used for filling small containers, such as vials and capsules.

3. Net Weigh Filling Machines:

Net weigh filling machines weigh the powder before dispensing it into containers. They provide high accuracy and are suitable for powders with varying densities.

4. Gross Weigh Filling Machines:

Gross weigh filling machines weigh the container before and after filling, determining the net weight of the powder. They are commonly used for filling large containers, such as sacks and barrels.

5. Form-Fill-Seal Machines:

These machines create the container from a roll of film, fill it with powder, and seal it. They are suitable for powders that require airtight packaging.

How Does a Chemical Powder Packing Machine Work?

The machine typically consists of a hopper that holds the powder, a dosing system that measures the desired amount, and a filling mechanism that transfers the powder into the container. The container is then sealed and labeled, completing the packaging process.

What Factors to Consider When Choosing a Chemical Powder Packing Machine?

When selecting a chemical powder packing machine, several crucial factors must be considered to ensure optimal performance and efficiency.

1. Product Characteristics:

The nature of the chemical powder, including its particle size, density, and flowability, significantly influences the machine’s design. Machines designed for fine powders require different mechanisms than those for coarse powders.

2. Packaging Requirements:

The desired packaging format, such as bags, pouches, or containers, determines the machine’s filling and sealing capabilities. Consider the target weight, shape, and material of the packaging.

3. Production Capacity:

Estimate the required production output to determine the machine’s speed and efficiency. High-volume operations may necessitate multiple machines or a high-speed model.

4. Accuracy and Consistency:

Precision filling is essential for accurate dosing and product quality. Consider the machine’s accuracy and consistency in meeting specified weight or volume requirements.

5. Safety and Compliance:

Chemical powders often pose safety hazards. Ensure the machine complies with industry regulations and safety standards, including dust containment and explosion protection.

6. Automation and Integration:

For automated production lines, consider the machine’s ability to integrate with other equipment, such as conveyors and palletizers. This enhances efficiency and reduces labor costs.

7. Maintenance and Serviceability:

Regular maintenance is crucial for optimal performance. Choose a machine with accessible components and easy-to-replace parts to minimize downtime and maintenance costs.

8. Cost and Return on Investment:

Consider the initial investment cost as well as ongoing operating expenses, such as energy consumption and maintenance. Evaluate the potential return on investment based on increased productivity and reduced labor costs.

9. Supplier Reputation and Support:

Choose a reputable supplier with a proven track record and reliable customer support. This ensures access to technical assistance, spare parts, and software updates.

10. Future Expansion:

Consider the potential for future production growth. Select a machine that can accommodate increased capacity or handle different product types to avoid costly upgrades or replacements.

What is the Future of Chemical Powder Packing Machines?

The future of chemical powder packing machines is bright, driven by advancements in technology and the increasing demand for automation. Here are some key trends to watch for:

- Increased Automation: Automation will continue to play a significant role in powder packing, reducing labor costs and improving efficiency.

- Smart Technology: Machines will become more intelligent, incorporating sensors and data analytics to optimize performance and minimize downtime.

- Sustainability: Environmental concerns will drive the development of eco-friendly machines that reduce waste and energy consumption.

- Customization: Manufacturers will offer customized solutions to meet the specific needs of different industries and applications.

Ideal Custom Packing Machine From BG Machinery

Chemical powder packing machines are essential tools for industries that handle and package powdered chemicals. By understanding the different types, benefits, and factors to consider, you can make an informed decision when selecting a machine that meets your specific requirements. With the right machine, you can optimize your packaging process, improve product quality, and enhance safety in your operations.

If you are unsure which machine would be a good fit for your company, BG Machinery can help you find the perfect machine for your needs. We have a wide selection of machines and knowledgeable staff who can answer any questions about automatic packaging machine .

Cut downtime by 30% with BG Machinery’s precision-engineered machines trusted by 100+ powder producers. Get started today to enjoy free customized solution design and experience factory on-site machine testing — let BG Machinery simplify your powder packaging machine selection process!

Want to get Chemical Powder Packaging Machine Price?

Why We're Different

As one of the top 5 E2E Smart Packaging Solutions Suppliers, we don’t just sell you equipment and move on. Our BG machinery engineers provide expert solutions to ensure your existing machinery operates efficiently.

We’re on the cutting edge of filling advancements. We developed the industry’s first fully automatic 4-side seal production line with robot hands for batch flexibility. Not only that, but our excellence extends throughout every phase of our collaboration.

Beyond that, our relentless innovation and proven excellence empower your success—so why wait? Get a free capacity diagnostic report ,customized ROI calculator and cost-effective packaging solution.