- Home

- Powder Filling Machine

- Detergent Powder Packing Machine

Detergent Powder Packing Machine

Customize Packaging Machine for Detergent Powder

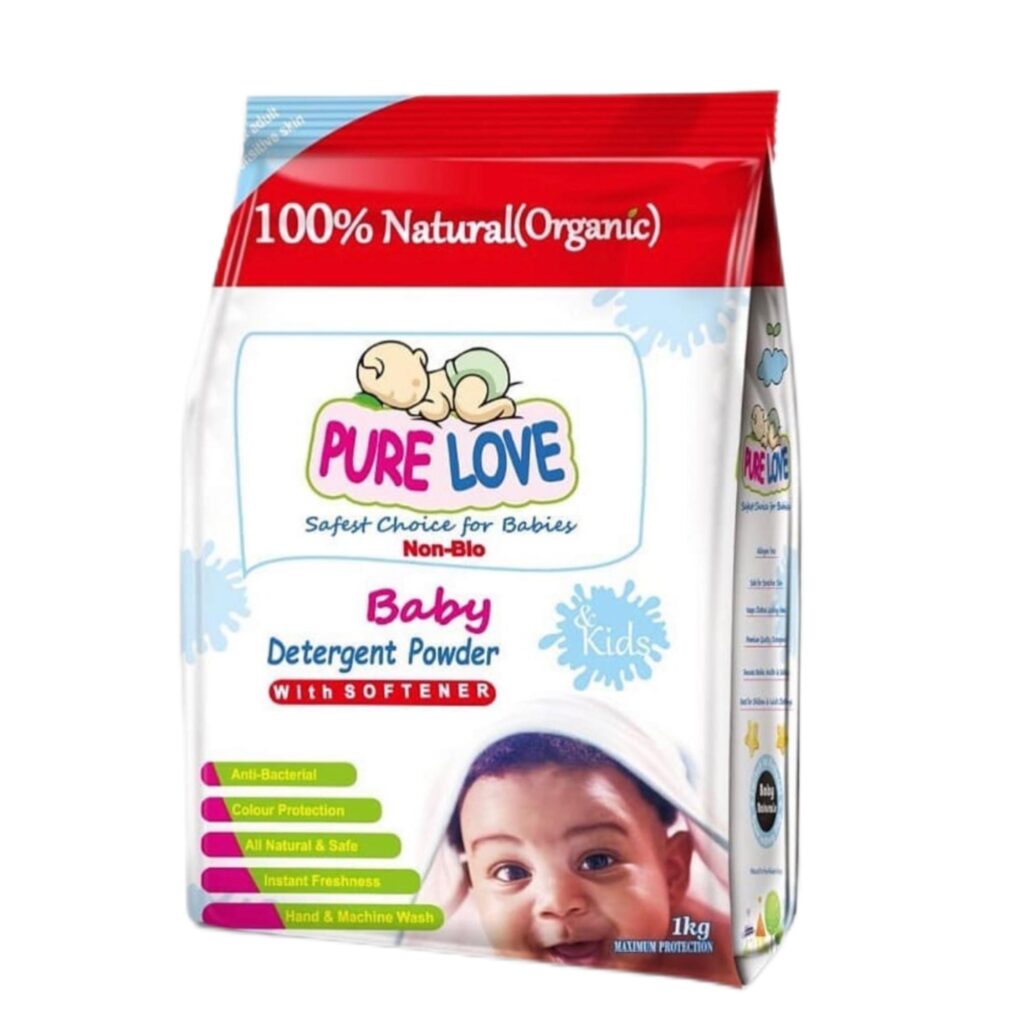

BG Machinery offers a wide range of detergent powder packaging equipments. 100+ washing powder manufacturers choose BG Machinery automated packaging and sealing machines for their ease of use, durability, and high speeds necessary for packaging carpet powder, alconox powder,meliora laundry powder, dishwashing powder, and cleaning powder products.

4 side seal , 3 side seal bag, Stick pack ,Stand up bag, Pillow bag, Quad seal bag and Flat bottom bag is avaliable

- Wide range of washing powder filling machine options

- High speed & Low failure

- Flexbile Package & Sustainabilty

- Competitive Price with reliable quality

- On time delievry & Perfect after-sales service

Detergent Powder Packaging Machine for Sale

Vertical Form Fill Seal Machine

Vffs machine automates the process of making bags from rolls of flat film, filling them with detergent powder, and then sealing them. The process involves vertical form-fill-seal (VFFS) techniques, making it efficient for large-scale production. It is ideal for producing sealed packages at high speeds

Detergent Pouch Packing Machine

Specifically designed to handle pre-made pouches, doypack machine fills the pouches with detergent powder and then seals them. This machine can handle various pouch sizes and types, adapting easily to different market demands

Auger Filling Machine

Auger Filler uses an auger to dispense precise amounts of detergent powder into containers or packages. The auger filling technique is particularly effective for maintaining consistent fill weights and reducing product waste. It's commonly integrated with both form fill seal machines and pouch packing systems to enhance their efficiency and accuracy

Video Gallery

Detergent Powder Packing Machine Video

Skyrocket Your Business with BG Machinery

How can we order the right machine?

How can we check your machine quality after we place an order?

You will receive photos and videos of the machine every 5-10 days so that you can assess its running condition. In addition, you’re welcome to check the machine by yourself at our factory.

Why we should choose you?

- Professional team 24 hours provide service for you

- 12 months warranty

- Life time technical support no matter how long you have bought our machine

- Oversea service is available.

What about your payment?

T/T by bank account directly, L/C at sight

Ultimate Guide

Detergent Powder Packing Machine: The Complete Guide 2025

Table of Contents

In the realm of household cleaning, detergent powder reigns supreme. To ensure its efficient distribution, detergent powder packing machines play a crucial role. These machines automate the packaging process, ensuring accuracy, speed, and hygiene.

What is a Detergent Powder Packing Machine?

A detergent powder packing machine is a specialized equipment designed to fill and seal pre-formed pouches or containers with detergent powder. It consists of a hopper that holds the powder, a filling system that dispenses the powder into the containers, and a sealing system that seals the containers.

What Equipment Is Used For Detergent Powder?

Detergent powder packing machines come in various types, each suited to specific production requirements. The most common types include:

- Vertical Form Fill Seal (VFFS) Machines: These machines form the pouches from a roll of film, fill them with powder, and seal them.

- Pre-Made Pouch Packing Machines: These machines fill pre-formed pouches with powder and seal them.

- Canister Filling Machines: These machines fill pre-formed canisters with powder and seal them.

What are the Benefits of Using a Detergent Powder Packing Machine?

Utilizing a detergent powder packing machine offers numerous benefits:

- Increased Efficiency: Automation reduces manual labor and increases production speed.

- Improved Accuracy: Machines dispense powder more accurately than manual filling.

- Enhanced Hygiene: Automated packaging minimizes the risk of contamination.

- Reduced Labor Costs: Machines eliminate the need for manual labor, saving on labor costs.

- Consistent Product Quality: Machines ensure consistent filling and sealing, resulting in high-quality products.

How Does a Detergent Powder Packing Machine Work?

The operation of a detergent powder packing machine is relatively straightforward. The powder is loaded into the hopper, and the machine automatically dispenses the desired amount into the containers. The containers are then sealed, typically using heat sealing or adhesive tape.

What are the Key Features to Consider When Choosing a Detergent Powder Packing Machin

When selecting a detergent powder packing machine, several crucial factors warrant consideration to ensure optimal performance and efficiency.

1. Production Capacity:

Determine the desired output capacity of the machine based on your production volume. Consider factors such as the speed of the machine, the size of the bags, and the number of filling heads.

2. Bag Type and Size:

Choose a machine compatible with the type and size of bags you intend to use. Consider the material, thickness, and dimensions of the bags to ensure proper sealing and filling.

3. Filling Accuracy:

Precision in filling is essential to avoid product waste and ensure consistent packaging. Look for machines with accurate weighing systems and adjustable filling nozzles to minimize variations.

4. Sealing Quality:

The sealing quality of the bags is crucial for product preservation and shelf life. Opt for machines with reliable sealing mechanisms, such as heat sealing or ultrasonic sealing, to ensure airtight and leak-proof packaging.

5. Automation Level:

Consider the level of automation desired. Manual machines require operator intervention, while semi-automatic machines offer partial automation, and fully automatic machines handle the entire process with minimal human involvement.

6. Maintenance and Service:

Regular maintenance is essential for optimal performance. Choose machines with accessible components, easy-to-replace parts, and reliable after-sales support to minimize downtime and ensure longevity.

7. Safety Features:

Safety should be a top priority. Look for machines with safety guards, emergency stop buttons, and other features to protect operators and prevent accidents.

8. Energy Efficiency:

Energy consumption can impact operating costs. Consider machines with energy-efficient designs, such as variable speed drives and optimized power consumption, to reduce energy usage.

9. Cost and Budget:

Determine the budget available for the machine and consider the initial investment, operating costs, and maintenance expenses. Compare different options to find the best value for your needs.

10. Supplier Reputation:

Choose a reputable supplier with a proven track record in the industry. Look for companies with positive customer reviews, reliable support, and a commitment to innovation.

By carefully considering these factors, you can select the ideal detergent powder packing machine that meets your specific requirements and ensures efficient and cost-effective packaging operations.

What are the latest advancements in Detergent Powder Packing Machines?

The detergent powder packing industry is constantly evolving, with new advancements emerging to enhance efficiency and productivity. Some of the latest advancements include:

- Automated feeding systems: These systems automatically feed detergent powder into the machine, reducing manual labor.

- Inline quality control systems: These systems inspect and reject defective packages, ensuring product quality.

- Remote monitoring and control: Advanced machines allow for remote monitoring and control, enabling real-time adjustments and troubleshooting.

How can I Maintain My Detergent Powder Packing Machine?

Regular maintenance is essential to ensure optimal performance and longevity of your detergent powder packing machine. Follow these tips:

- Clean the machine regularly: Remove any detergent powder residue or debris to prevent blockages.

- Inspect and replace worn parts: Regularly check for worn or damaged parts and replace them promptly.

- Lubricate moving parts: Lubricate all moving parts according to the manufacturer’s instructions.

- Calibrate the machine: Periodically calibrate the machine to ensure accurate filling and sealing.

Ideal Custom Packing Machine From BG Machinery

Detergent powder packing machines are essential equipment for the efficient and hygienic packaging of detergent powder. By understanding the different types, key features, and benefits of these machines, manufacturers can make informed decisions to optimize their production processes and meet the growing demand for detergent powder.

If you are unsure which machine would be a good fit for your company, BG Machinery can help you find the perfect machine for your needs. We have a wide selection of machines and knowledgeable staff who can answer any questions about automatic packaging machine .

Cut downtime by 30% with BG Machinery’s precision-engineered machines trusted by 100+ powder producers. Get started today to enjoy free customized solution design and experience factory on-site machine testing — let BG Machinery simplify your powder packaging machine selection process!

Want to Get Washing Powder Packing Machine Price?

Why We're Different

As one of the top 5 E2E Smart Packaging Solutions Suppliers, we don’t just sell you equipment and move on. Our BG machinery engineers provide expert solutions to ensure your existing machinery operates efficiently.

We’re on the cutting edge of filling advancements. We developed the industry’s first fully automatic 4-side seal production line with robot hands for batch flexibility. Not only that, but our excellence extends throughout every phase of our collaboration.

Beyond that, our relentless innovation and proven excellence empower your success—so why wait? Get a free capacity diagnostic report ,customized ROI calculator and cost-effective packaging solution.