Powder Pouch Packing Machine

- Home

- Packing Machine

- Premade Pouch Packing Machine

- Powder Pouch Packing Machine

Feature

- Siemens PLC control system

- Robust stainless steel frame and parts

- No pouch—no fill sensor

- Color touchscreen

- Automatic film tracking

- Wide application:food,non-food and phamacy.

- Fill measure accurately 99.99%

- Convenient adjustment and full automation.

- Super maintence&On time delivery

- Competitive price and reliable quality

- OEM&ODM is avaliable

Video Gallery

Powder Pouch Packing Machine Video

Powder Pouch Packing Machine is engineered to package powdered products, this machine typically utilizes an auger filler system to dispense precise amounts of product into pouches. Our powder pouch-packing machinery is suited for all industries as your first pouch-filling machine:

Pharmaceutical Packaging

In the pharmaceutical industry, the machine is used for packing powders such as antibiotics, vitamins, and pain relievers. The need for a sterile environment and precise dosages makes the powder pouch packing machine an ideal choice.

Food and Beverage Industry

For food and beverage manufacturers, the machine is used to package a variety of powdered products, including spices, powdered drinks, and condiments. The focus here is on preserving flavor and freshness.

Cosmetics and Personal Care

In the cosmetics industry, the powder pouch packing machine is used for packaging products like face powders, body powders, and other cosmetic powders. The emphasis is on maintaining the product’s integrity and appearance.

Agricultural Products

Fertilizers, pesticides, and other agricultural powders are also packaged using these machines. The focus is on ensuring the product’s effectiveness and ease of application.

Summary

2. The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch..

3. Automatic checking system can check bag situation, filling and sealing situation. The system shows 1.no bag feeding, no filling and no sealing. 2.no bag opening/opening error, no filling and no sealing 3.no filling, no sealing..

4. The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

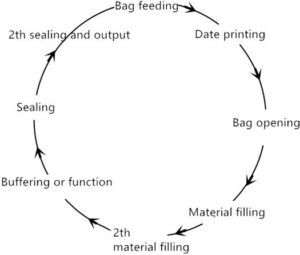

Working Process

The Filling Process

The heart of the machine, the filling process, is where the powder is measured and dispensed into the pouch. High-speed cameras and sensors work together to ensure that the filling is accurate to the last milligram.

Sealing Technology

Sealing is the next critical step, where heat and pressure are applied to fuse the edges of the pouch together. Advanced sealing technologies ensure that the pouch remains intact, preserving the product’s freshness and quality.

Automation and Control Systems

The integration of automation and control systems allows for minimal human intervention, reducing the risk of contamination and increasing the speed of production.

Sample Bag

Attention: If the bag sizes fall outside of the specified range, we will offer customization options to fulfil any unique size requests.

- Zipper/Resealable/Ziplock bag packaging —— between zipper and bag mouth distance at least 2.5cm.

- Gusset bag packaging —— bag gusset width within 50mm, if the bag mouth is too small the products can’t fill completely, and can’t be packed.

- Spout bag packaging —— spout at the side of the bag, sealing sizes at least 50mm.

- Pallet bag packaging —— pallet in bags, pallet length lower bag mouth at least 3cm.

Machine Structure

FAQ

Q1: What types of powder pouch packing machines does your company provide?

A: We offer a variety of granule premade pouch packing machines. Based on your powder type, packaging requirements, and production capacity, we can provide suitable model options. Please browse our product catalogue for information on the features and specifications of each model.

Q2: Can your powder pouch filling and sealing machines accommodate different bag types and sizes?

A: Yes, our pouch-packing machines can accommodate various bag types and sizes. Our machines are equipped with flexible adjustment capabilities to accommodate different sizes of premade bags, including stand-up pouches, four-side seal bags, and more. We can provide bag type adjustments and customization services based on your specific requirements.

Q3: How automated are your powder pouch packing machines?

A: Our premade pouch packing machines for powder are highly automated. They are equipped with advanced control systems and sensors to automate bag filling, measuring, sealing, and coding processes. Through precise and reliable automation technology, our machines enhance production efficiency and packaging quality.

Q4: Can you provide technical support if I encounter issues while using the premade pouch packing machine?

A: Absolutely! We provide comprehensive technical support. Whether it’s during the installation and debugging stage or while using the machine, our technical team is available to provide support and training. We offer remote support through phone or video conferences to address your queries and concerns, ensuring the smooth operation of your packaging machine.

Q5: Do your packaging machines come with a warranty? How long is the warranty period?

A: Yes, our packaging machines come with a 1-year warranty. We provide a specified warranty

LTC8-200 | LTC8-260 | LTC8-300 | |

Bags size | W:80~210mm L:100~300mm | W:120~250mm L:100~400mm | W:200~300mm L:100~400mm |

Bag type | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag |

Filling Volume | 30–1900g depending on the type of products | 30-2000g depending on the type of products | 100-2500g depending on the type of products |

Capacity | 25-60 bags/min for different materials and different bag | 25-60 bags/min for different materials and different bag | 25-60 bags/min for different materials and different bag |

Dimension | 1.140*1.500*1.560m | 2.46*1.83*1.46m |

|

Weight & power supply | 400kgs/1500kgs/1600kgs-1800kgs 380v 50HZ 3P 2.5kw-5kw | ||

Compress air requirement | 0.6-1m³/min supply by user | ||

Working flow | 1. Bag feeding | ||

Related Machine

Custom Pouch Packaging Machine

Client Testimonials

Why We're Different

As industry-leading filling and packaging machine manufacturers, we don’t sell you equipment and move on. BG machinery engineers offer expert solutions to keep your existing machinery efficient.

We’re on the cutting edge of filling advancements. We developed the industry’s first fully automatic 4 side seal production line with robot hands for batch flexibility. Not only that, but you will also find our excellence extends beyond just that during the collaboration.