Introduction

Spices are the essence of diverse cuisines, providing flavors, aromas, and vibrant colors that enhance every dish. The path from farm to table is filled with obstacles, especially when it comes to maintaining the quality and freshness of these invaluable ingredients. Here is where spice packaging machines take center stage. These advanced machines are crafted to streamline the packaging process, guaranteeing uniformity, cleanliness, and optimal efficiency.

As consumers become more aware of the quality and source of their food, the importance of packaging is more significant than ever. Smart packaging safeguards spices from contamination and degradation while boosting their shelf life and visual allure. Additionally, as e-commerce and global trade continue to expand, the need for dependable packaging solutions is at an all-time high.

This blog will take you on a journey through the realm of spice packaging machines, highlighting their various types, advantages, and essential considerations for selecting the perfect fit for your business. We will tackle common questions and offer valuable insights supported by pertinent statistics to empower you in making informed decisions. This guide is your ultimate resource for everything you need to know about spice packaging machinery, whether you’re aiming to enhance your current packaging line or start a brand new project.

Why Spice Packaging Machines Matter

Keeping Freshness and Flavor Intact

Spice packaging machines play a crucial role in maintaining the freshness and flavor of spices. Air, moisture, and light can greatly diminish the quality of spices, resulting in a decline in potency and aroma. Cutting-edge packaging machines utilize methods such as vacuum sealing and nitrogen flushing to establish the perfect environment, enhancing shelf life and preserving the quality of the spices.

Prioritizing Cleanliness and Security

In the culinary world, maintaining impeccable hygiene and safety standards is essential. Manual packaging processes often face the risk of contamination, potentially jeopardizing product quality and posing health risks. Automating the spice packaging process not only cuts down on human involvement but also significantly lowers the chances of contamination. Swift packaging lines guarantee that spices are efficiently packed, preserving a sterile environment and complying with rigorous food safety standards.

Boosting Efficiency and Productivity

Manual packaging demands significant time and effort, making it both a lengthy and laborious process. Spice packaging machines enhance the efficiency of the packaging process, boosting production rates and cutting down on labor expenses. Today’s advanced machines come packed with capabilities such as automatic filling, sealing, labeling, and even palletizing, allowing manufacturers to effortlessly and accurately meet high demand.

Enhancing Product Attraction and Brand Identity

In the current competitive landscape, packaging stands out as a crucial differentiator. Spice packaging machines provide tailored solutions that empower businesses to create eye-catching and practical packaging. Selecting the perfect material and size, along with integrating brand logos and labels, these machines craft packaging that safeguards the product while captivating consumers and strengthening brand identity.

How Many Types of Spice Packaging Machines?

Understanding the different types of spice packaging machines is essential for selecting the right equipment that aligns with your production needs and business goals. Here are the most common types:

1. Vertical Form Fill Seal (VFFS) Machines

VFFS machines are widely used in the spice industry due to their versatility and efficiency. These machines form packages from a flat roll of film, fill them with the desired amount of spice, and seal them shut. VFFS machines can handle a variety of packaging materials, including plastic, foil, and biodegradable films, making them suitable for different product requirements.

Advantages:

- High-speed production

- Flexible packaging options

- Automated operation

Applications:

- Bulk and retail packaging

- Sachets and pouches

- Stand-up and flat-bottom bags

2. Auger Fillers

Auger fillers are specifically designed for accurately dispensing powders and granular materials like spices. They use a rotating auger to measure and transfer the spice into the packaging container. These machines are known for their precision and consistency, ensuring that each package contains the exact quantity of product.

Advantages:

- High accuracy and consistency

- Suitable for a wide range of powdery products

- Easy integration with other packaging systems

Applications:

- Bulk packaging

- Sachets and small containers

- Automated filling lines

3. Multi-head Weighers

Multi-head weighers are used for high-speed and high-volume spice packaging. They feature multiple weighing heads that operate simultaneously, allowing for rapid and precise filling of large quantities. These machines are ideal for businesses with significant production demands and require quick turnaround times.

Advantages:

- Exceptional speed and throughput

- High precision

- Minimal product wastage

Applications:

- Large-scale manufacturing

- Commercial and industrial packaging

- Automated production lines

4. Vacuum Packing Machines

Vacuum packing machines remove air from the packaging before sealing, which helps in preserving the freshness and extending the shelf life of spices. These machines are particularly useful for spices that are sensitive to oxygen and require airtight packaging to maintain their quality.

Advantages:

- Enhanced product preservation

- Extended shelf life

- Improved packaging aesthetics

Applications:

- Premium and gourmet spices

- Long-term storage packaging

- Specialty spice blends

How To Choosing a Spice Packaging Machine?

Selecting the right spice packaging machine involves evaluating several critical factors to ensure it meets your production requirements and business objectives. Here are the key features to consider:

1. Production Capacity

Assess your current and projected production volumes to determine the machine’s capacity. It’s essential to choose a machine that can handle your peak production needs without compromising on speed or efficiency. Consider future growth and scalability to avoid frequent upgrades.

2. Type of Packaging

Different spice packaging machines support various packaging types and materials. Determine the packaging format that best suits your product and target market, whether it’s pouches, bags, sachets, or bottles. Ensure the machine is compatible with your chosen packaging materials, such as plastic, foil, or biodegradable films.

3. Automation Level

The level of automation can significantly impact your production efficiency and labor costs. Fully automated machines offer higher speed and consistency, reducing the need for manual intervention. Semi-automated or manual machines may be suitable for smaller operations with lower production demands.

4. Precision and Accuracy

Accuracy in filling and sealing is crucial for maintaining product quality and customer satisfaction. Look for machines with precise measurement systems and consistent sealing capabilities. Features like adjustable fill volumes and fine-tuning options can enhance accuracy and reduce product wastage.

5. Ease of Operation and Maintenance

User-friendly interfaces and intuitive controls simplify machine operation, reducing the learning curve for your staff. Additionally, consider the ease of maintenance and availability of spare parts. Machines with modular designs and easy access to components can minimize downtime and maintenance costs.

6. Hygiene and Safety Standards

Ensure the packaging machine complies with relevant hygiene and safety standards, especially if you’re operating in the food industry. Features like stainless steel construction, sealed components, and easy-to-clean surfaces help maintain a sanitary environment and prevent contamination.

7. Integration with Existing Systems

Evaluate how well the packaging machine integrates with your current production line and other equipment. Seamless integration ensures smooth workflow, minimizes disruptions, and enhances overall productivity. Compatibility with existing systems can also streamline operations and reduce setup time.

8. Cost and ROI

Consider the total cost of ownership, including the initial purchase price, installation costs, maintenance expenses, and energy consumption. Assess the return on investment (ROI) by analyzing how the machine’s efficiency and productivity gains can offset the costs over time. Look for machines that offer a balance between affordability and functionality.

9. Technical Support and Warranty

Reliable technical support and comprehensive warranties are essential for addressing any operational issues and ensuring long-term performance. Choose manufacturers or suppliers that offer prompt customer service, training, and after-sales support to keep your packaging line running smoothly.

Frequently Asked Questions (FAQs) About Spice Packaging Machines

1. What are the benefits of using automated spice packaging machines?

Automated spice packaging machines offer numerous benefits, including increased production speed, enhanced accuracy, reduced labor costs, improved hygiene, and consistent packaging quality. Automation also allows for scalability, enabling businesses to meet growing demand without significant manual intervention.

2. How do spice packaging machines preserve the freshness of spices?

Spice packaging machines preserve freshness by using advanced sealing techniques that protect spices from air, moisture, and light. Vacuum sealing and nitrogen flushing are common methods employed to create an airtight environment, preventing oxidation and moisture ingress that can degrade spice quality.

3. What types of packaging materials can be used with spice packaging machines?

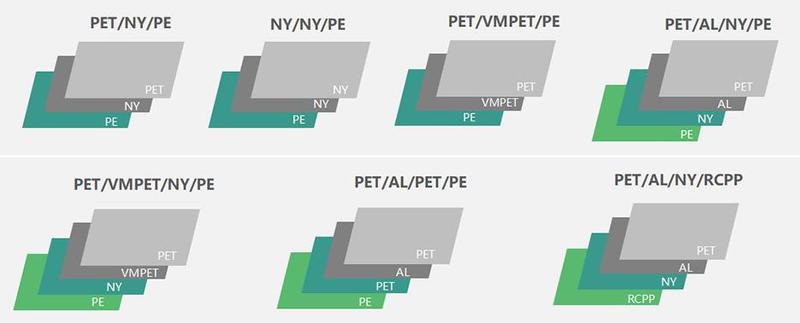

Spice packaging machines are compatible with a variety of materials, including plastic films (polyethylene, polypropylene), foil, laminated films, and biodegradable materials like paper-based films. The choice of material depends on factors such as product type, shelf life requirements, and environmental considerations.

4. Are spice packaging machines suitable for small-scale businesses?

Yes, there are spice packaging machines designed for small-scale operations. These machines offer lower production capacities and are often semi-automated or manual, providing flexibility and affordability for businesses with limited budgets and lower production volumes.

5. How can I maintain my spice packaging machine for optimal performance?

Regular maintenance is crucial for ensuring the longevity and efficiency of your spice packaging machine. This includes routine cleaning, lubricating moving parts, inspecting for wear and tear, and promptly addressing any mechanical issues. Following the manufacturer’s maintenance schedule and guidelines can prevent breakdowns and maintain consistent performance.

6. What are the latest trends in spice packaging technology?

Recent trends in spice packaging technology include the adoption of smart packaging solutions with QR codes and NFC tags for traceability, the use of sustainable and eco-friendly materials, the integration of automation and robotics for enhanced efficiency, and the implementation of advanced sealing techniques to improve product preservation.

7. How do I choose the right spice packaging machine for my business?

Choosing the right spice packaging machine involves evaluating your production capacity, desired packaging type, level of automation, precision needs, budget, and compatibility with existing systems. It’s also essential to consider the reputation of the manufacturer, available technical support, and the machine’s compliance with industry standards.

8. Can spice packaging machines handle different spice varieties?

Yes, spice packaging machines are designed to handle a wide range of spice varieties, including powders, granules, and flakes. Machines equipped with adjustable settings and versatile filling mechanisms can accommodate different product consistencies and packaging formats.

9. What is the average lifespan of a spice packaging machine?

The lifespan of a spice packaging machine varies based on factors such as usage intensity, maintenance practices, and build quality. On average, well-maintained machines can last between 5 to 15 years. Investing in high-quality equipment and adhering to regular maintenance schedules can extend the machine’s operational life.

10. How do spice packaging machines contribute to sustainability?

Spice packaging machines contribute to sustainability by enabling the use of eco-friendly packaging materials, reducing product wastage through precise filling, and enhancing energy efficiency with modern technology. Additionally, automated machines optimize resource utilization and minimize environmental impact through streamlined operations.

Conclusion

In the competitive and dynamic spice industry, efficient and reliable packaging is a cornerstone of success. Spice packaging machines offer a myriad of benefits, from preserving the freshness and flavor of spices to enhancing production efficiency and boosting product appeal.

By understanding the different types of packaging machines, evaluating key features, and staying abreast of industry trends, businesses can make informed decisions that drive growth and customer satisfaction.

Investing in the right spice packaging technology not only streamlines operations but also reinforces your commitment to quality and sustainability. With over 40,000 machines installed in more than 190 countries, we have nearly 20 years of proven experience, with a strong focus on the factory of tomorrow with advanced systems, line engineering and innovation. Contact Us Today !