Are you struggling to improve your factory productivity?

Looking for ways to reduce your packing staff,,increasing your product output, and reach higher packing speeds?

As the sales manager of BG Pack ,I have finished 500+ projects,and help 200+ partners build their dream factory .

What if I told you that you can increase your packing speed by 25%, 50%, or even 100%?

What if I told you that you can reduce your operators by 1 or 2 people, cut down on costs, and realize dramatic productivity gains?

It is possible and easily achievable.

How?

By automating your packing process through installing a Automatic Packaging System to your production line.

Today, we’ll talk about the Automatic packer: What it is, its pros and cons, and when it makes sense for your company versus when there are better options you should consider.

What is Automatic Packer and Packing Process?

Maybe you’re curious about what the best automatic packer is?

An automatic packer is a machine designed to package products efficiently without the need for constant human intervention. These systems are commonly used in industries such as food and beverage, pharmaceuticals, e-commerce, and consumer goods.

Automatic packers operate by integrating various technologies like sensors, conveyors, and robotic arms to handle, seal, and pack items. The process typically involves:

- Product Feeding: Items are fed into the machine through a conveyor belt.

- Sorting and Grouping: The machine organizes products based on size, weight, or type.

- Packaging: Items are placed into boxes, bags, or cartons, which are then sealed for shipment.

Advanced models may incorporate AI and IoT technologies to monitor and adjust packing processes in real-time for maximum efficiency.

How to Choose the Right Automatic Packer

There are Manual packing systems, Semi-Automatic packing systems, Automatic packing systems, and Fully-Automatic packing systems.We will dive into it how to choose alone.

Manual Packing

Manual packing involves human operators performing the entire packing process by hand. This type is ideal for small businesses or operations with low production volumes. It is cost-effective initially but may not scale well as demand increases.

Pros: Low initial cost and High flexibility for varying product types

Cons: Time-consuming and High labor costs

Semi-Automated Packing

Semi-automated packers combine manual labor with mechanical assistance. Operators place products in position, and the machine handles specific tasks like sealing or grouping.

Pros: Faster than manual packing and Reduced physical strain on workers

Cons: Still requires significant human intervention

Automated Packing

Automated packers take over most packaging tasks, requiring minimal operator input. These machines are suitable for businesses with moderate to high production needs.

Pros: Efficient and consistent and Reduces errors

Cons: Higher upfront cost than manual or semi-automated systems

Fully-Automated Packing

Fully-automated packers are the pinnacle of packaging technology, performing every step of the process without human intervention. Advanced models can also adapt to product variations automatically.

Pros:Maximum efficiency and accuracy and Best for high-volume operations

Cons: Significant initial investment and Requires trained personnel for maintenance

Is An Automatic Packer Truly the Right Machine for Your Company?

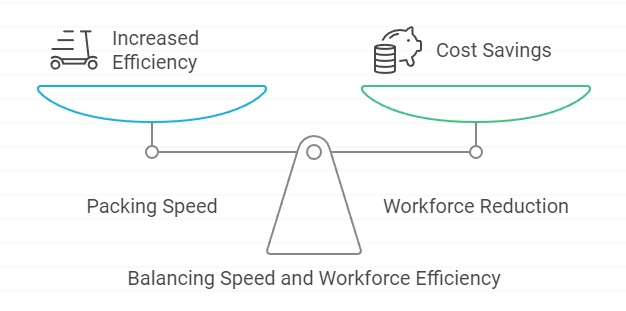

I Think the question of whether an automatic packer is suitable for your company often comes down to balancing efficiency, versatility, and cost. While the allure of fully automated systems can be compelling, a closer look at the realities of their implementation provides valuable insights for informed decision-making.

The Allure of Automation

Many businesses are drawn to the idea of robots handling all packaging processes autonomously, imagining reduced labor costs and improved efficiency. However, , humans play a significant role in automated processes

- Semi-Automated Packers: Require active operator involvement in the packing process, such as loading cases or managing outputs.

- Automated Packers: Limit operator involvement to tasks like feeding materials into the machine or addressing issues, but their presence is still essential.

The Reality Check: Automation vs. Human Adaptability

Automation struggles to fully replicate the nuanced movements and adaptability of human hands.

For example:

- A Pouch or Box sticking out of place? A human adjusts it instinctively.

- Complex or irregular shapes? Humans adapt seamlessly, while robots often fail.

Robots excel at repetitive tasks in well-defined, consistent environments but falter when variability arises. This limitation underscores the importance of humans in automated processes, especially when handling complex or unconventional packaging scenarios.

The Cost of Fully Automated Systems

While fully automated systems offer speed and consistency, they come with significant drawbacks:

High Costs: Building machines that imitate every human movement with zero errors is not only complex but extremely expensive.

Lack of Versatility: Machines excel in repetitive tasks but struggle when the process requires adjustments or flexibility.

Risk of Downtime: A fully automated machine failing to handle unexpected changes could cause costly operational delays.

The tradeoff between versatility and performance often tips the scale in favor of solutions that balance human adaptability with automation.

Efficiency vs. Cost: Key Considerations

- If your production volume is high and uniform, an automated packer might provide long-term savings.

- For businesses that deal with varied packaging needs or irregular shapes, semi-automated systems could deliver similar efficiency at a lower cost.

- Always consider the hidden costs of automation, such as maintenance, training, and potential downtime.

Frequently Asked Questions About Automatic Packers

Q1. What industries benefit the most from automatic packers?

Answer: Industries such as food and beverage, e-commerce, pharmaceuticals, and manufacturing see the most significant benefits. These sectors require high-volume packaging and value consistency.

Q2. Are automatic packers expensive?

Answer: While the upfront cost ranges from $10,000 to over $100,000 depending on the model, businesses typically recover the investment within a few years through labor and material savings.

Q3. Can small businesses use automatic packers?

Answer: Yes! Compact and budget-friendly models are available for small businesses, making automation accessible even for startups.

Q4. How much maintenance do these machines require?

Answer: Regular maintenance, such as cleaning, lubrication, and occasional part replacements, ensures optimal performance. Most manufacturers provide maintenance schedules and service contracts.

Q5. What safety features do automatic packers have?

Answer: Safety features like emergency stop buttons, safety guards, and sensors prevent accidents during operation.

Ready to Take the Next Step?

At BG Pack, we understand that each business has unique packaging requirements. Our team of experts is ready to help you analyze your needs and find the perfect packaging solution that balances efficiency, cost, and operational excellence.

Contact us today to discuss how we can help optimize your packaging operations and drive your business forward. With over 500 successful projects and 200+ satisfied partners, we’re here to help you build the efficient, profitable factory you’ve always dreamed of.

Remember: The right packaging solution isn’t just about speed – it’s about creating sustainable, efficient operations that drive long-term success for your business.