介紹

In the modern world, the demand for poultry products has significantly increased due to their nutritional value and affordability. As a result, the increased demand for poultry products has led to the expansion of the poultry business, requiring the development of efficient and sanitary packaging methods. Poultry packing machines play a crucial role in ensuring that products reach consumers in top condition and comply with the strictest cleanliness and food safety standards. (Volz) (Food Processing and Packaging Equipment, Norway) (Guerrero-Legarreta et al.)

Types of Poultry Packing Machines

Vacuum Packing Machines

Vacuum packing machines are widely used for retail meat, seafood, and poultry products. They help extend the shelf life of the products by removing air from the packaging, preventing the growth of bacteria and other microorganisms.

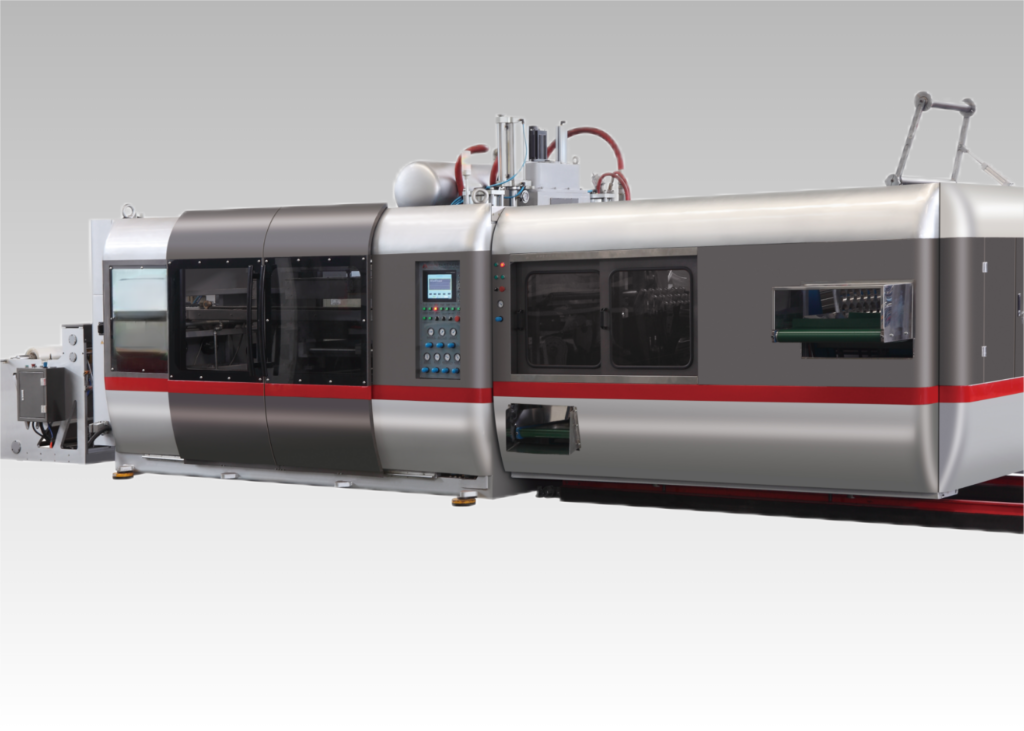

Thermoforming Machines

These machines are highly efficient and fully automatic, designed for packaging a variety of poultry, beef, meat, and fish products. They use stretch film to create vacuum-sealed packages that maintain product freshness and hygiene..

Horizontal packing machines

Designed specifically for packaging whole fresh or frozen chickens into bags, these machines are typically made from stainless steel to ensure durability and hygiene.

Importance of Poultry Packing Machines

Ensuring Quality Standards

The poultry packaging process begins with the inspection of the birds to ensure they meet the required quality standards. Any defective or unfit birds are removed from the production line to prevent contamination of the final product. Once the birds have been inspected, they are cleaned thoroughly to remove any dirt, feathers, or other debris. This step is crucial for maintaining food safety, as it helps prevent the spread of bacteria and other pathogens.

Enhancing shelf life and traceability

After cleaning, the birds are weighed and labelled to provide consumers with accurate information about the product’s weight and origin. This labelling process is crucial for traceability, enabling the identification of any potential product issues and facilitating the recall of affected products when needed. The poultry packaging machine then comes into play, automatically packaging the birds in a hygienic and efficient manner. The machine uses a combination of vacuum sealing and modified atmosphere packaging (MAP) to extend the shelf life of the products and maintain their quality.

Reducing Cross-Contamination

Using a poultry packaging machine helps minimise the risk of cross-contamination. These machines are designed to handle multiple birds simultaneously, reducing the amount of human contact with the products. This is particularly important in the poultry industry, where the risk of contamination is high due to the presence of pathogens such as Salmonella and Campylobacter.

High-Quality Packaging Materials

Another important aspect of poultry packaging is the use of high-quality materials. The packaging must be strong enough to protect the birds during transportation and storage while also being easy to open and dispose of. The use of recyclable packaging materials helps reduce waste and promote sustainability.

結論

Poultry packaging machines play a vital role in ensuring the hygiene and food safety of poultry products. By automating the packaging process, these machines help to minimise the risk of contamination and cross-contamination while also extending the shelf life of the products. Furthermore, the use of high-quality materials and efficient packaging techniques helps to maintain the quality of the products and reduce waste. As the demand for poultry products continues to grow, it is essential that the industry invest in advanced packaging solutions to meet the increasing demands for hygiene and food safety.

Works Cited

Food Processing and Packaging Equipment, Norway. 1983,

Guerrero-Legarreta, Isabel, et al. Handbook of Poultry Science and Technology, Secondary Processing. John Wiley and Sons, 2010,

Volz, Marvin Dudley. Systems and Equipment for Packaging and Price Marking Meat and Poultry in Retail Food Stores. 1967,